Throughout the history of human engineering, sending equipment into space has been one of the greatest challenges for designers. Systems destined for locations above the atmosphere are subject to some of the harshest conditions known to humanity. While some Earth-based applications may experience greater temperature or pressure extremes, the cumulative environmental challenges of interstellar orbit make space design uniquely difficult.

Environmental Challenges in Space

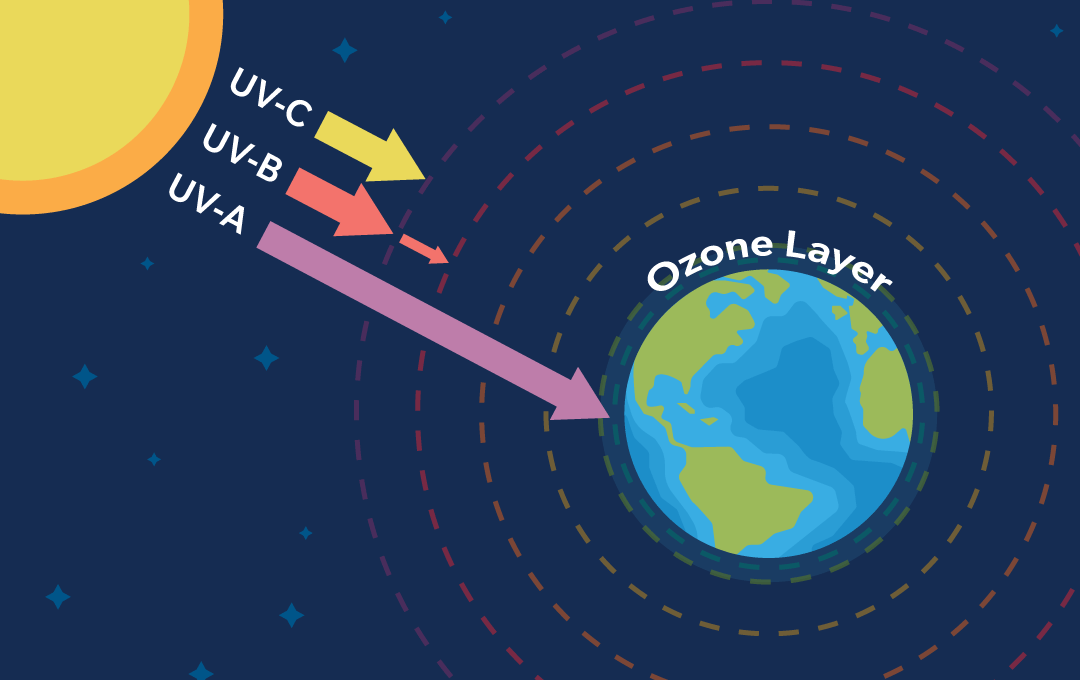

The conditions found in space are unlike any that can be created naturally on earth. The most obvious is the complete absence of the atmosphere which serves as a blanket that protects both humans and equipment. Above the atmosphere’s protection, devices are exposed to the full force of the sun’s radiation.

Figure 1: Objects in space are exposed to increased levels of UV radiation.

The atmosphere also provides thermal insulation. Without it, objects must contend with extremes of temperature. Equipment that is exposed to direct sunlight becomes very hot, whilst devices that remain in shadow can rapidly drop to subzero temperatures. When designing any device that needs to operate in these extremes, the materials selected must be capable of surviving such a wide variation in temperatures.

The Effects of Vacuum and Rigors of Launch

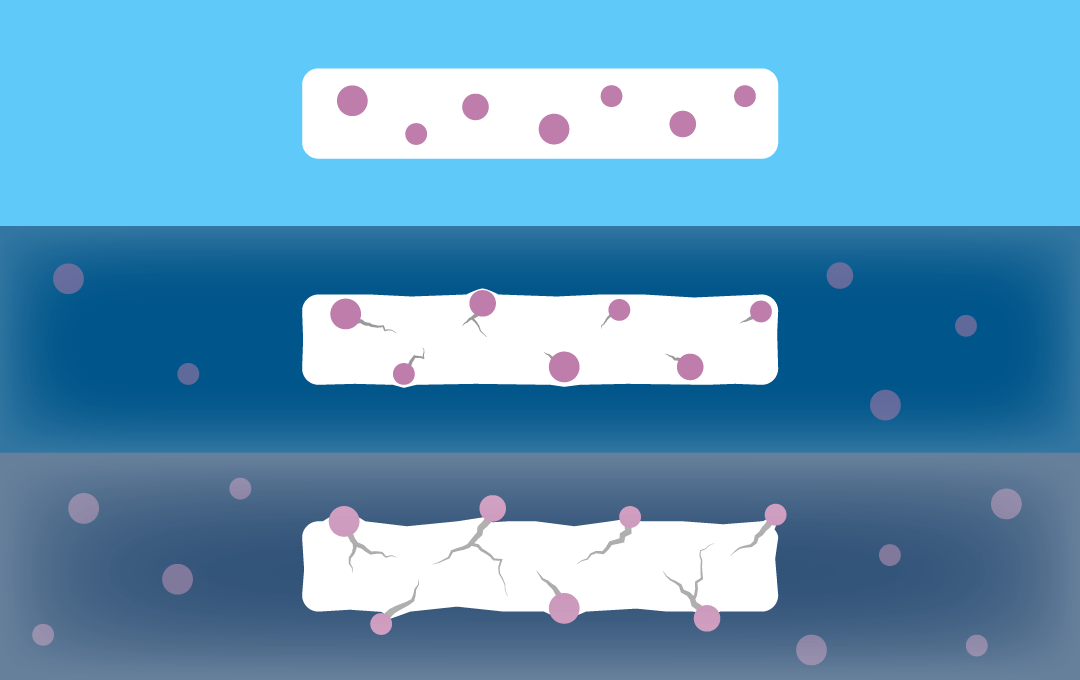

The absence of atmospheric pressure also causes some materials to behave in unique ways. The manufacturing process of some plastics results in gas becoming trapped within their structure. Outgassing is a physical process in which this trapped gas is released when exposed to vacuum, such as that found in spaceflight. The released gas can then condense onto cold surfaces. If these surfaces are part of the optics or sensors of scientific equipment, the reduction of capability can place the entire mission at risk.

Figure 2: Gas bubbles in a material can migrate causing fractures and damage to the component.

Components are also exposed to the rigors of launch into orbit. Not only do rockets exert a sustained acceleration on equipment during launch, they also create vibration and shock. The forces involved can be extreme, and equipment must be designed to withstand them without failure.

The Difficulty of Repair in Space

These conditions in isolation are not unique to the space industry. Components in scientific and aerospace applications are often exposed to extremes of temperature, while shock and vibration is found in a wide range of applications, from motorsport to industrial machinery. However, the final challenge facing equipment destined for space is the lack of any chance for repair.

There have been a few high-profile instances of equipment being repaired in space. The Hubble space telescope is a prime example. However, the realities of how space is currently being used means this is generally no longer possible. NASA’s space shuttle, the only realistic platform for such repairs, has long been retired, preventing such large high-profile operations from occurring in the same way.

The Challenges of Commercial Space Applications

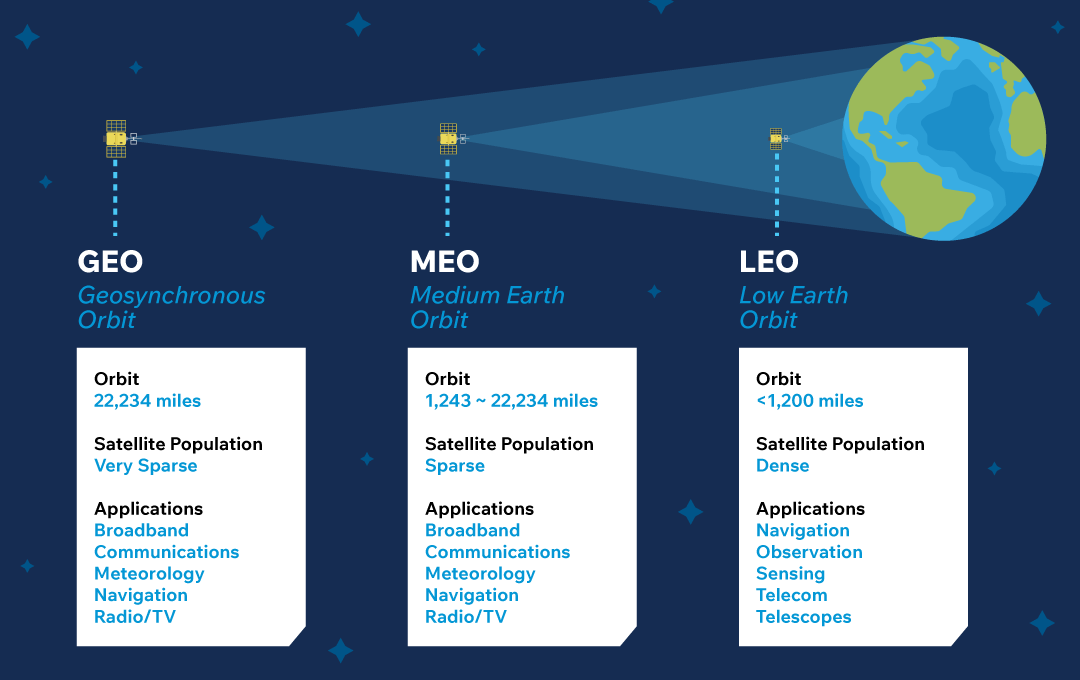

The growing commercialisation of space is changing the economic landscape. During the Space Shuttle program, the cost of launching equipment into Low Earth Orbit (LEO) was more than $50,000 per kilogram. Advances in technology and the emergence of competition mean that today’s launch systems can perform the same task at a cost of less than $3,000 per kilogram.

Figure 3: Regions of Space, Low Earth Orbit (LEO), Medium Earth Orbit (MEO), and Geosynchronous Orbit.

Despite the new economics of space and the availability of cheaper launches, space-based systems still need to perform reliably for extended periods in the toughest environment, without the possibility of repair. Whether working in the scientific or commercial sectors, engineers need a way to ensure that the components they choose for their designs can cope with the demands of spaceflight. Long-term, high-volume testing of individual components is expensive and time consuming, and so to deliver the confidence that designers need, NASA has created the Technology Readiness Levels (TRL) system.

What Are Technology Readiness Levels?

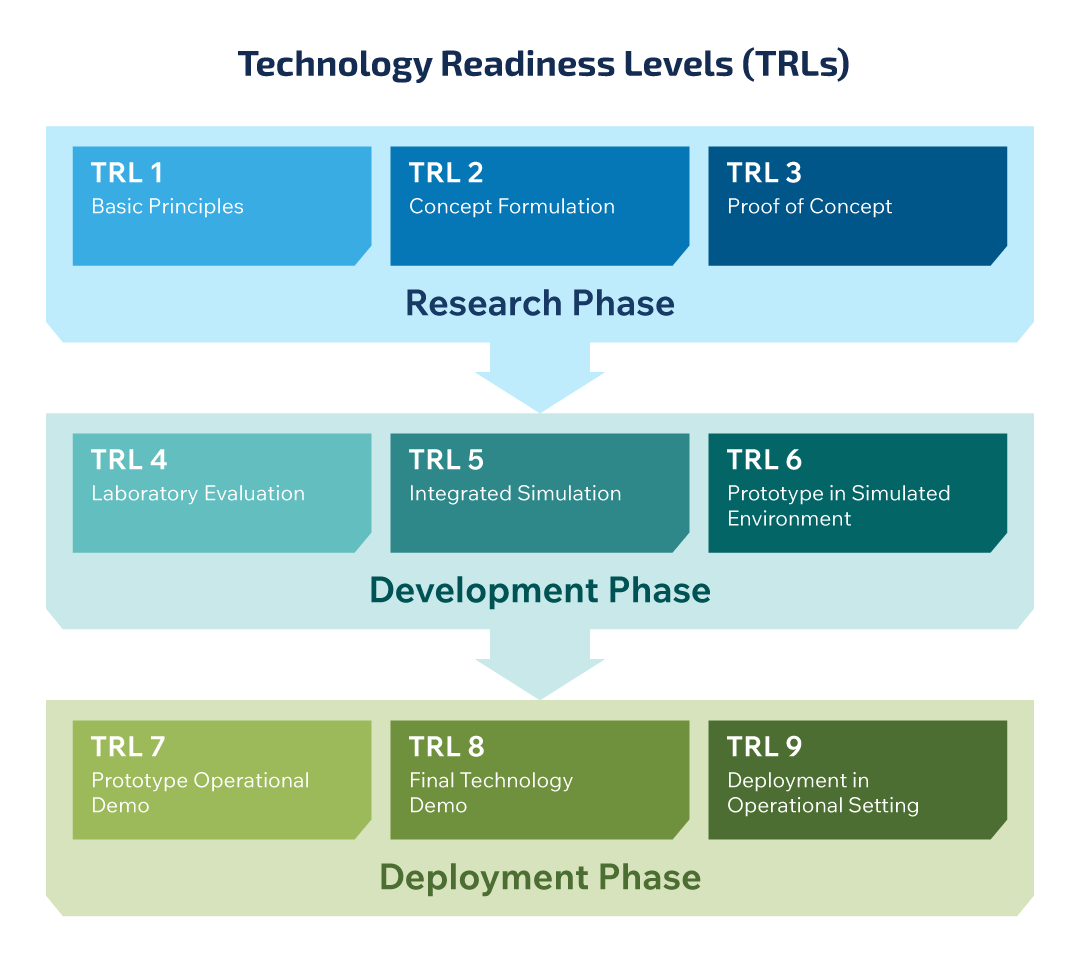

The TRL concept is a clearly defined measurement system that can assess the maturity level of a particular technology. It can be applied to many different aspects of space-based equipment, from individual components to complete systems including software. Each item is assigned a TRL of between 1 and 9, depending on the stage of its development, the extent of the testing to which it has been subjected, and, ultimately, its performance in a real-world spaceflight application.

The lowest level represents a component or technology in its initial stage of development. A concept has been created, and designers will have described the engineering or science behind its operation. By level 4, a physical mock-up will be created to prove the function of the component technology, but at this stage it is not a production-ready design, nor will it withstand the rigorous testing regime that a space-ready component must undergo.

A component at level 7 will be close to the form that a final product would take, meaning it has been subjected to standard operational testing to prove its functionality. This testing takes place in recreations of the environment for which the component was designed, ensuring it is ready for production.

Once a product has completed all the extensive testing engineers require to ensure performance in the toughest of conditions, it will advance to level 8. However, the final proof of any product’s suitability can only be obtained by use in a real application.

Level 9 therefore represents the pinnacle of performance for any component. Not only will it have completed a long and complex development program and satisfied the most stringent of tests, it will have also proven itself in space. The level 9 component will have successfully been deployed aboard a mission and performed at or above its expected performance. It can be selected for new systems with the highest level of confidence that can only be delivered by practical experience.

Figure 4: Technology Readiness Levels stages of development.

Applying TRLs to Component Selection

The importance of choosing components with a proven track record of success in spaceflight operations is exacerbated by the unique nature of this industry. In the automotive or consumer sectors, manufacturers can create large numbers of prototypes and test them in real-world situations. The release of a product can be delayed until trials are completed, allowing the customer to buy with confidence.

These trials are impractical in the spaceflight industry. The cost and complexity of space-based equipment means that it is too expensive to create enough prototypes for extensive ground-based testing. In addition, the unique environment found in space cannot be fully replicated on Earth, and the extended duration of many space programs is a further barrier to meaningful tests.

These concerns have faced designers from the earliest days of space exploration. Indeed, it became a major consideration in the Apollo program. The need to return the astronauts to Earth placed safety and reliability in the spotlight during the design phases of the program. From the smallest component to the mightiest rocket, engineers needed to create the safest possible system.

Unlike the Apollo engineers, 60 years of spaceflight now provides the modern designer with a legacy of proven technology upon which they can draw. Choosing a component that has earned the highest TRL allows designers to build confidence into their system before it even leaves the ground.

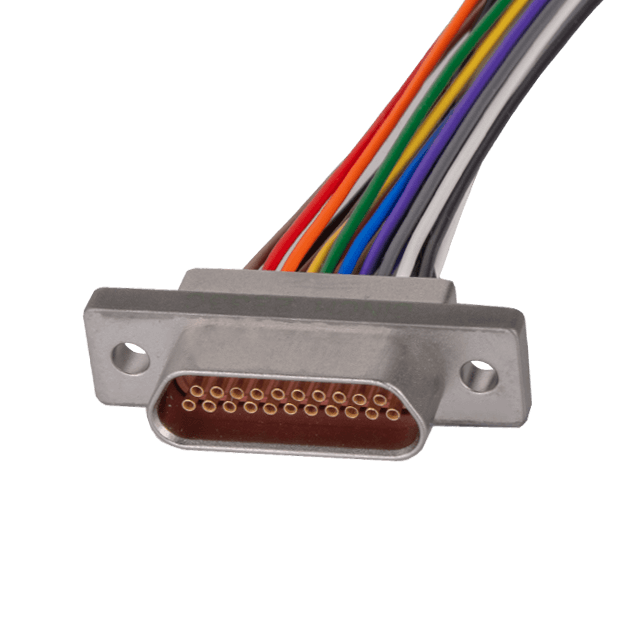

Cinch’s Space Qualified Connectors

Components intended for the challenges of space must deliver reliability and confidence. The highest level of confidence is provided by components that have proven themselves in the toughest conditions. The reliability of Cinch space-qualified connectors, cables, terminations, and attenuators has seen them prove themselves in successful missions over many years.

From NASA's Apollo to ESA's Sentinel, Cinch components have been part of some of the most famous space programs in history, visiting Mars, Jupiter's moons, and the Sun. They have even reached interstellar space aboard the Voyager probes. With decades of service in some of the most challenging conditions known to mankind, Cinch components have earned the highest TRL levels.

Visit Cinch.com for more information.

Space Screened Micro-D Plugs

Space Screened Micro-D Plugs

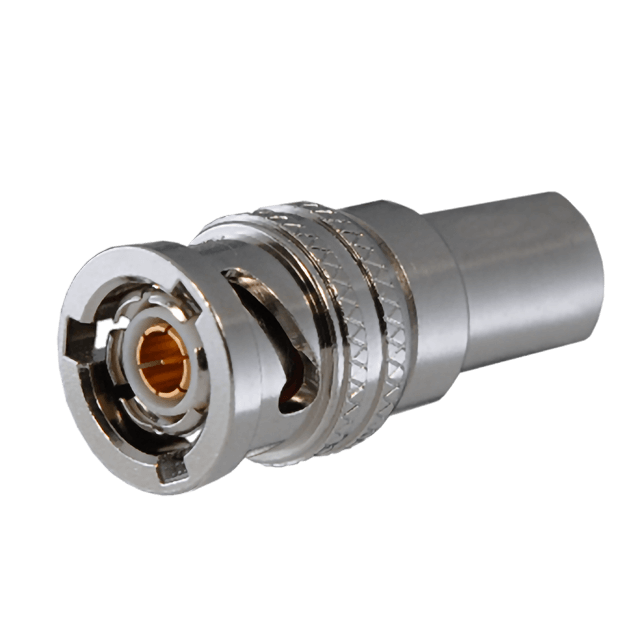

QPS Attenuators: Qualified Parts for Space

QPS Attenuators: Qualified Parts for Space

Trompeter Space Ready Products

Trompeter Space Ready Products