Why Contact Technology Matters in High-Reliability Systems

In high-reliability electronic systems, where failure is not an option, connectors serve as critical enablers of performance and durability. Across aerospace, defense, medical, and industrial applications, even the smallest design choices can affect system integrity. One such factor is the contact technology used within miniature connectors that meet the MIL-DTL-83513 Micro-D standard.

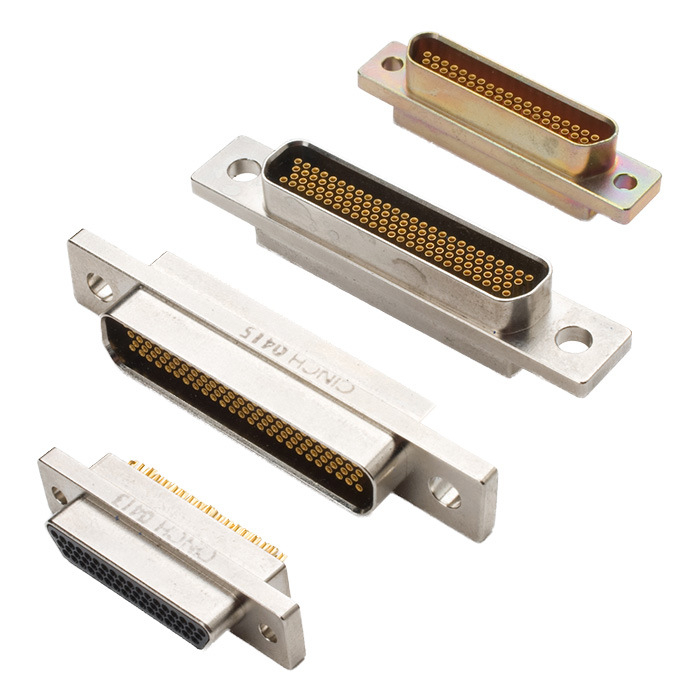

Although many Micro-D connectors comply with baseline specifications, their internal contact design, whether stamped and formed or twist pin, can dramatically influence vibration resistance, contact stability, and long-term durability. This article examines the unique role of Cinch Dura-Con connectors with twist-pin contacts. Though no longer proprietary, twist-pin technology, originally developed by Cinch, continues to deliver superior performance under extreme conditions.

Figure 1: MIL-DTL-83513 Micro-D Connector Socket Example (note: plug uses twist pins, which are housed in protective wells due to reverse gender design).

For engineers specifying components in satellite payloads, rugged defense platforms, or compact medical devices, understanding contact mechanics is critical. In high-reliability environments, what happens at the micro-contact level can determine mission success. NASA mandates the use of twist pin contacts for Micro-D connectors in INST-EEE-002, and many defense system integrators also require them for mission-critical applications.

Stamped and Formed Contacts: A Cost-Effective Standard with Reliability Limits

Stamped and formed contacts are widely used in many Micro-D connector designs. Manufactured by stamping thin sheet metal and forming it into spring-like shapes, these contacts are cost-effective and conducive to high-volume production. They maintain contact pressure using one or more flexible tines or beams within the mating interface.

Although stamped contacts can meet the performance thresholds outlined in the Military Detail Specification MIL-DTL-83513, they have inherent limitations in high-reliability environments. These contacts typically provide only two or three discrete mating points, which limits redundancy. If one point degrades due to fretting, oxidation, or wear, overall contact resistance may increase significantly, raising the risk of failure.

Mechanical resilience is another concern. Under conditions involving vibration, shock, or thermal cycling, stamped contacts may experience micro-motion or contact instability, resulting in intermittent connections. Their thin walls and sharp bend radii also increase susceptibility to fatigue and stress fractures over time.

Crimp integrity poses an additional challenge. Because stamped contacts use thin, formed metal, achieving a reliable, gas-tight crimp, especially at miniature sizes, is difficult. Some manufacturers compensate by adding secondary processes, such as spot welding, which adds both complexity and potential failure points.

While stamped and formed contacts are suitable for commercial and benign environments, they often lack the mechanical and electrical robustness required for mission-critical systems. In such cases, Cinch's twist-pin contact offers a more reliable alternative.

Twist-Pin Contacts: Engineered for High-Reliability Performance

In high-reliability environments, connector performance often hinges on contact design. Cinch’s twist-pin contact departs from conventional stamped-and-formed methods to deliver a mechanically superior and electrically stable interface.

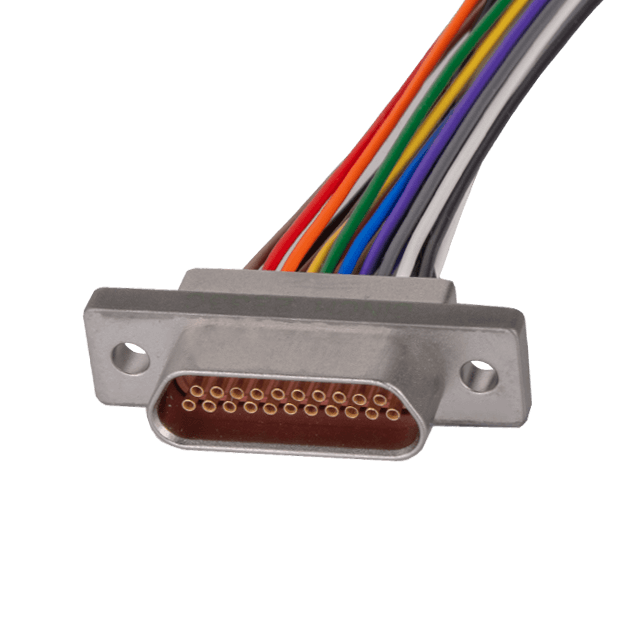

Figure 2: 8-Pin MIL-DTL-83513 Micro-D Connector, side view of Cinch twist pin showing helical geometry, and front view illustrating multiple micro-contact points for redundant engagement.

Unlike stamped contacts formed from sheet metal, Cinch’s twist pin is manufactured by winding multiple strands of high-conductivity wire into a precision-controlled helix. At designated points, the strands are fused, via welding, soldering, or crimping, to maintain the structure and ensure continuous electrical conductivity. The outer wires of the twist pin are gold plated beryllium copper, which is harder, stronger, and more durable than standard copper, providing superior spring characteristics and long-term durability.

This design forms a characteristic bulge at the mating end of the pin. Upon insertion into a corresponding socket, the helix compresses slightly, generating uniform radial pressure and establishing multiple micro-contact points, typically seven or more. This redundancy enhances reliability: if one contact point degrades due to fretting or contamination, others maintain the electrical path. The twist-pin and machined socket interface also serve to minimize mating damage by shielding pins in recessed wells and leveraging socket geometry for additional strength.

Manufacturing precision is critical. Each twist pin is produced to strict tolerances for helix geometry, contact diameter, and plating thickness. This consistency ensures predictable insertion force, stable contact resistance, and batch-to-batch uniformity. Furthermore, the solid-wire construction enables a robust, gas-tight crimp at the rear termination—reducing the need for reinforcement processes such as spot welding.

In essence, the twist-pin design delivers redundancy, uniform pressure distribution, and enhanced crimp performance. These characteristics translate into superior resistance to vibration, shock, and thermal cycling, making Cinch’s Dura-Con twist-pin Micro-D connectors ideal for mission-critical systems that comply with MIL-DTL-83513.

Performance Advantages: Vibration Resistance, Crimp Integrity, and Redundant Contact Paths

In mission-critical systems, performance is not solely defined by initial conductivity, it is measured by long-term reliability under mechanical and environmental stress. Cinch’s twist-pin contact technology is engineered for precisely these demands, offering distinct advantages that extend the lifespan and dependability of MIL-DTL-83513 Micro-D connectors. These advantages align with stringent aerospace and defense requirements, including NASA’s INST-EEE-002 and similar specifications adopted by leading defense contractors. While this design carries a higher upfront cost, its long-term reliability makes it a smart investment for systems expected to operate over an extended period.

Figure 3: Close-Up of Cinch Twist Pin Contact bulged mating end compresses upon insertion to create uniform radial pressure and multiple micro-contact points.

1. Vibration and Shock Resistance

Twist-pin contacts are inherently resilient in environments subject to vibration, motion, or mechanical shock. Their helical bundle design distributes normal force across multiple micro-contact points, maintaining continuous engagement with the socket. This spring-like interface absorbs stress while preserving electrical continuity, reducing risks of intermittent signals, fretting corrosion, and micro-motion failures, common issues with stamped contacts. Twist pin connectors withstand up to 500 G shock and 200 G vibration, significantly outperforming the 50 G shock and 20 G vibration ratings of standard M83513 connectors using stamped contacts.

2. Consistent Contact Resistance

The combination of high normal force and multi-point engagement ensures low and stable contact resistance throughout the connector’s service life. Twist pin contacts provide lower contact resistance, typically around 3 mΩ compared to 8 mΩ for standard M83513 connectors. This reliability minimizes signal degradation and supports predictable performance, even as surfaces oxidize or wear. Twist-pin redundancy compensates for environmental or mechanical degradation, helping preserve signal integrity in applications such as aerospace or defense systems.

3. Robust Crimp Integrity

Crimp joints are a known point of failure in miniature connectors, particularly with thin stamped contacts. Cinch’s twist pins, composed of solid or bundled wire, provide greater contact area and material strength for forming gas-tight, mechanically secure crimps. This enhances joint durability and reduces the need for secondary reinforcement, such as spot welding, streamlining assembly while improving long-term reliability.

4. Engagement and Pin Protection

The engagement between Cinch’s twist pin and machined socket reduces the risk of turned-back pins during mating by ensuring precise alignment and resilient contact pressure. Cinch’s reverse-gender design places the male pins in recessed wells within the connector housing, shielding them from bending or damage during engagement. The exposed female sockets, machined with a larger outer diameter, provide structural strength and absorb mating force. This geometry enhances durability and maintains connector integrity through repeated mating cycles and mechanical stress.

5. Built-In Redundancy

Stamped contacts often provide only two or three contact points. In contrast, twist-pin contacts deliver seven or more, ensuring functional redundancy. If individual points are compromised by contamination or wear, others maintain the electrical path. This fault tolerance is critical for systems requiring uninterrupted performance over decades.

6. Resistance to Thermal and Environmental Stress

Twist pins adapt effectively to temperature fluctuations, humidity, and other environmental extremes. Their flexible geometry and distributed contact pressure maintain stable engagement across thermal cycles and mechanical shifts. Combined with high-quality plating and strict manufacturing tolerances, this makes Cinch’s twist-pin contacts ideal for harsh operating environments.

7. Machined Sockets Construction for Superior Reliability

In addition to twist-pin contact design, Cinch Dura-Con connectors feature precision-machined sockets rather than stamped or formed alternatives. Machined sockets provide tighter dimensional control, smoother mating surfaces, and improved contact alignment, resulting in lower contact resistance and greater durability over time.

When Stamped Contacts Are Sufficient

While twist-pin contacts provide superior performance for mission-critical systems, not all applications require the highest level of reliability. In certain scenarios, stamped and formed contacts remain a practical and cost-effective solution.

In controlled environments, such as laboratory instrumentation, stationary medical devices, or commercial-grade electronics, connectors may experience minimal vibration, limited thermal cycling, and infrequent mating cycles. Under these conditions, stamped contacts can deliver adequate electrical performance without the added complexity or cost of twist-pin designs.

However, it is important to assess the complete system risk profile. Even in seemingly benign environments, factors such as unanticipated vibration, mechanical shock, or environmental exposure can introduce long-term reliability risks. In such cases, the added performance margin of twist-pin contacts may be justified.

Ultimately, connector selection should reflect the application’s reliability requirements, tolerance for failure, and lifecycle cost. For non-critical systems, stamped contacts may suffice. For high-reliability designs, especially those governed by MIL-DTL-83513 standards, twist-pin contacts offer a proven advantage.

Design and Specification Tips for Connector Selection

Choosing the right contact technology in a Micro-D connector requires more than verifying MIL-DTL-83513 compliance. Engineers must evaluate environmental conditions, mechanical stressors, and the long-term reliability demands of the application. The following guidelines can assist in specifying the most appropriate contact design, particularly for high-reliability systems.

1. Evaluate Performance Beyond MIL-DTL-83513

The MIL-DTL-83513 specification defines baseline requirements for Micro-D connectors but does not distinguish between internal contact types. Two connectors may both meet the spec, yet exhibit vastly different real-world performance. Always request detailed qualification data, particularly for contact resistance stability, vibration endurance, and mating cycle durability.

2. Balancing Budget and Mission Requirements

Weigh cost against operational lifespan and reliability demands. In high-reliability environments, especially those with long service cycles, the premium for twist-pin and machined socket designs is justified by their performance over time. For short-term or benign applications, stamped contacts may suffice, but for mission-critical systems, investing in robust contact technology pays dividends in durability and system integrity.

3. Prioritize Redundancy for High-Reliability Applications

Twist-pin contacts offer multiple micro-contact points, often seven or more, compared to just two or three in stamped designs. This built-in redundancy increases fault tolerance, helping maintain electrical continuity in the presence of fretting, wear, or contamination. In mission-critical systems, redundancy directly contributes to long-term reliability.

4. Assess Termination Strength and Solderability

While Cinch Micro-D connectors do not employ crimped contacts, the integrity of the contact-to-wire or contact-to-board connection remains critical. Twist-pin designs often support stronger internal geometries, improved solderability, and better mechanical retention. These attributes reduce risk in environments requiring robust termination and encapsulation.

5. Align Contact Design with Mating Cycle Demands

Systems that involve frequent connector engagement, such as test fixtures or modular defense hardware, require contacts that maintain performance over time. The spring-like behavior of twist-pin contacts helps preserve normal force and reduce wear, even across thousands of mating cycles.

6. Consider Total Lifecycle Risk

Although stamped contacts can lower initial component costs, the potential cost of field failure may be significantly higher. In environments with vibration, thermal variation, or mechanical shock, the performance margin offered by twist-pin connectors reduces lifecycle risk and improves system availability.

7. Engage Early with the Manufacturer

Suppliers such as Cinch Connectivity provide qualification data, technical documentation, and direct engineering support. Early collaboration with application engineers ensures the selected connector aligns with both the electrical and mechanical demands of the system, not just the base requirements of the specification.

Contact Reliability Begins with Design

In high-reliability applications, the smallest components often carry the greatest responsibility. Within Micro-D connectors, contact design plays a pivotal role in sustaining electrical performance, especially under conditions involving vibration, thermal cycling, and extended operational life.

Stamped and formed contacts may meet baseline specifications and perform adequately in stable environments. However, they lack the redundancy, mechanical integrity, and durability needed for mission-critical systems. Cinch’s twist-pin contact, featured in Dura-Con Micro-D connectors, offers a field-proven solution engineered for extreme conditions. Its spring-loaded helical geometry, multiple micro-contact points, and robust termination interface work together to ensure consistent electrical continuity and mechanical resilience.

Whether the application involves satellite systems, defense platforms, or ruggedized medical equipment, specifying the correct contact technology from the outset is essential. Twist-pin contacts reduce system-level risk, extend product lifespan, and help ensure long-term performance compliance, particularly under MIL-DTL-83513 standards.

To learn more about Cinch Dura-Con twist-pin technology and its performance in demanding environments, contact our engineering team. We offer detailed datasheets, qualification test reports, and application-specific design guidance.

Dura-Con Micro-D Connectors

Dura-Con Micro-D Connectors

Space-Screened Micro-D Connectors

Space-Screened Micro-D Connectors

MIL-DTL-83513 Micro-D Connectors

MIL-DTL-83513 Micro-D Connectors