Designing Connectors for Space and Satellite Systems

Humanity has looked to the stars for millennia, but it wasn’t until seven decades ago that we took our first step beyond Earth’s atmosphere. In the intervening time, space-exploration has evolved into a thriving global industry, offering countless opportunities. From simple weather observations and imaging to high-speed communications and even tourism, space is now big business.

Despite these advances, space remains one of the most extreme environments that designers face. It is home to a wide range of conditions, some unique to the space environment, while others are extreme versions of those found on Earth. Designers must familiarize themselves with these conditions and their effects on materials and technology.

This article will highlight the five key considerations for designers working with space and satellite systems. Each section will outline the challenges that the environment poses and will deliver the design strategies that can mitigate them. Together, an understanding of these factors will allow designers to make informed choices when connector solutions need to withstand the rigors of orbital and deep-space environments.

1. The Vacuum of Space: Outgassing and Material Selection

The most defining feature of space is the absence of atmosphere. Without the pressure exerted by an atmosphere, there is no convective heat transfer and no protection from radiation. This vacuum creates unique challenges for connectors, both in material selection and mechanical behavior.

A major concern caused by vacuum conditions is outgassing. Outgassing is the release of gases trapped inside another material when exposed to vacuum conditions. While some metals are prone to this effect in vacuum conditions, including zinc and cadmium, the main source of concern comes from plastics.

Figure 1: Gas bubbles in a material can migrate causing fractures and damage to the connector.

If this occurs during spaceflight, the released gas can cause damage. It may condense onto cold surfaces such as the optics and sensors of scientific equipment. This can degrade or even negate their effectiveness and put the entire mission at risk. A notable example occurred during the Stardust mission. Launched in 1999, the Stardust spacecraft experienced contamination of its navigation camera due to outgassing from onboard materials, which potentially compromised its ability to capture images of the comet Wild 2.

Preventing outgassing is therefore essential. All components chosen should comply with the strict low-outgassing requirements of standards such as NASA ASTM E595 or ESA PSS-01-702. The goal is to ensure that total mass loss (TML) and collected volatile condensable materials (CVCM) remain within limits.

Connectors intended for spaceflight applications rely on vacuum-stable materials such as polyimide, PEEK, or glass-filled DAP. Metal surfaces are carefully plated with gold or nickel to prevent molecular migration or surface degradation. For Cinch engineers, maintaining vacuum compatibility is the first and most fundamental step in achieving a truly space-qualified interconnect system.

2. Radiation: Effects on Space Connectors and How to Mitigate Them

The absence of an atmosphere has other effects. Space is home to high levels of ionizing and non-ionizing radiation. Objects on the Earth’s surface are surrounded by the protective atmosphere which, when combined with the Earth’s magnetosphere, acts as a shield, protecting them from radiation. In contrast, objects in deep space are exposed to cosmic rays, solar particles, and trapped radiation belts. Radiation can degrade materials over time, weakening insulation, increasing leakage currents, and damaging plating layers. These effects can lead to embrittlement or electrical instability, both of which can compromise mission-critical equipment.

Figure 2: Different types of UV radiation and their interaction with common materials.

Combating the effects of deep space requires designers to employ radiation-hardened materials that maintain dielectric and mechanical properties, even after prolonged exposure. Polyimide and PTFE are well suited for these applications due to their stability under ionizing radiation, while ceramics provide outstanding insulation for high-dosage environments. Gold and nickel plating remain the preferred surface finishes for metals due to their excellent corrosion resistance and stable contact resistance when exposed to radiation.

| Radiation Source | Effect on Connectors | Mitigation Strategy | Recommended Materials |

|---|---|---|---|

| Cosmic Rays | Insulation degradation | Use radiation-hardened insulators | Polyimide, PTFE, ceramic insulators |

| Solar Particles | Increased leakage currents | Shielding and stable dielectric materials | Gold/nickel plating, PTFE, polyimide |

| Trapped Radiation Belts | Metal embrittlement | Corrosion-resistant plating and structural shielding | Gold/nickel plating, titanium alloys, stainless steel |

Table 1: Radiation Sources in Space, Their Effects on Connectors, and Mitigation Strategies

Shielding can also play a role at the system level. The strategic placement of connectors within the spacecraft structure, combined with localized shielding, can help reduce the risks posed by radiation exposure. Cinch’s interconnect solutions are qualified to perform under such conditions, ensuring consistent electrical reliability even in high-radiation orbital or deep-space missions.

3. Extreme Temperatures: Thermal Cycling and Material Strategies

The vacuum environment has a major impact on thermal management. When exposed to direct sunlight, spacecraft experience extreme temperature swings. Without the thermal insulation provided by the Earth’s atmosphere, temperatures can range from +125°C in sunlight to –150°C when in shadow. This wide range of temperatures creates cyclic expansion and contraction stresses on connectors, risking material fatigue and even fracture.

Figure 3: Harsh conditions faced in the vacuum of space.

To mitigate these effects, designers rely on a combination of material strategies and mechanical design features, including:

- Matching the coefficient of thermal expansion (CTE) between metals and insulators to minimize mechanical strain.

- Using spring-loaded or compliant contact systems (such as twist-pin designs) to absorb differential movement while maintaining stable mating force and low contact resistance.

- Machining structural components from thermally stable alloys like aluminum or titanium, which offer low mass and excellent resistance to thermal cycling, or stainless steel, which provides superior strength and durability.

- Applying corrosion-resistant plating such as gold or nickel to protect against surface degradation caused by temperature extremes.

Components are qualified through rigorous thermal vacuum (TVAC) testing to verify that they can endure the combined effects of temperature extremes and vacuum. Cinch’s interconnect systems undergo comprehensive environmental testing to ensure that each interconnect system maintains stable performance across repeated temperature cycles. This includes assemblies built with passivated stainless steel, which offers exceptional dimensional stability and corrosion resistance under thermal stress. These rigorous tests and trusted materials provide a vital safeguard for both short-term missions and multi-year deep-space deployments.

4. Mechanical Forces: Withstanding Launch Shock and Vibration

Although the conditions found in space are extreme, the most intense mechanical stresses occur during launch. The forces required to accelerate a vehicle into orbit are enormous. Components are subjected to sustained periods of high G-forces, along with shock and vibration. Even after the vehicle has reached a stable orbit, it will still experience vibrations and G-forces caused by thrusters, gyroscopes, and other onboard systems. It is also important to remember that the moment of launch is the culmination of months or even years of assembly and testing activities.

To address these challenges, designers must select connectors specifically engineered for harsh launch and orbital conditions. The table below outlines key mechanical stress factors and the corresponding design strategies used to mitigate them:

| Mechanical Challenge | Source of Stress | Design Strategy | Supporting Standards |

|---|---|---|---|

| High G-forces during launch | Rocket acceleration | Secure locking systems (bayonet, threaded, latched) | MIL-STD-202, ECSS-Q-ST-70-38 |

| Shock and vibration | Launch, thrusters, gyroscopes | Lightweight metal housings for durability and low mass | MIL-STD-202 |

| Cable strain and termination stress | Movement and vibration during orbit | Strain relief features and backshells | ECSS-Q-ST-70-38 |

Table 2: Mechanical Stress Factors and Connector Design Strategies for Spaceflight

Cinch connectors also incorporate strain relief features and backshells to distribute cable loads evenly, reducing stress on vulnerable termination points. Environmental qualification testing using the MIL-STD-202 and ECSS-Q-ST-70-38 standards ensures that connectors withstand the conditions experienced during spaceflight without fear of failure. For assemblies exposed to intense vibration or launch shock, robust materials like stainless steel often play a supporting role in maintaining structural integrity. The result is mechanical resilience that maintains electrical continuity from launch to orbit.

5. Reliability: Ensuring Long-Term Operation in Space-Grade Connectors

In 2015, the New Horizons probe conducted a flyby of Pluto, giving humanity its first close-up images of the dwarf planet. But because of the enormous distances that it had to traverse, New Horizons was traveling at such speed that it had a few scant hours to conduct its mission. If a critical system had failed, engineers on the ground would have had few options to recover the failed functionality.

While New Horizons provides an extreme example, all satellites and space systems operate for years, far from the possibility of repair. Every connector must function flawlessly throughout the mission, regardless of duration or environmental stress. Reliability in space-grade connectors therefore hinges on both robust design and comprehensive testing.

To ensure long-term performance, engineers employ several reliability-enhancing strategies:

- Redundant contact paths to provide fault tolerance in critical signal or power lines.

- EMI/RFI shielding to protect against interference from onboard electronics and external radiation sources.

- Corrosion-resistant plating, such as gold or nickel, to maintain stable contact resistance over time.

- Use of durable structural materials like passivated stainless steel, which offer excellent resistance to fretting, corrosion, and material creep

- Qualification to MIL-DTL and ECSS standards, verifying that connectors meet the rigorous demands of spaceflight.

Cinch validates its interconnect systems through the use of extensive testing programs that simulate mission conditions found in long-term operations. By qualifying to MIL-DTL and ECSS standards, Cinch ensures that every connector is built for the highest levels of reliability, providing the foundation of mission success.

Building Space-Qualified Connectors for Mission Success

Space exploration demands more from engineering than any other environment. From the vacuum and radiation of deep space to the stresses of launch and thermal cycling, every aspect of connector design must balance electrical performance, mechanical strength, and long-term reliability. Once deployed, these systems need to perform flawlessly for years, with little possibility of intervention.

For Cinch, meeting these demands is a matter of practical, effective engineering, creating the standard to which every space-qualified interconnect is built. Drawing on decades of experience in high-reliability applications, Cinch engineers design and test each system to ensure dependable operation under the most extreme conditions. The result is a portfolio of interconnect solutions that enable the next generation of spacecraft to operate with confidence, resilience, and absolute reliability.

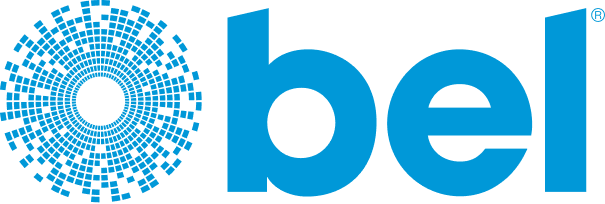

Space-Screened Micro-D Plugs

Space-Screened Micro-D Plugs

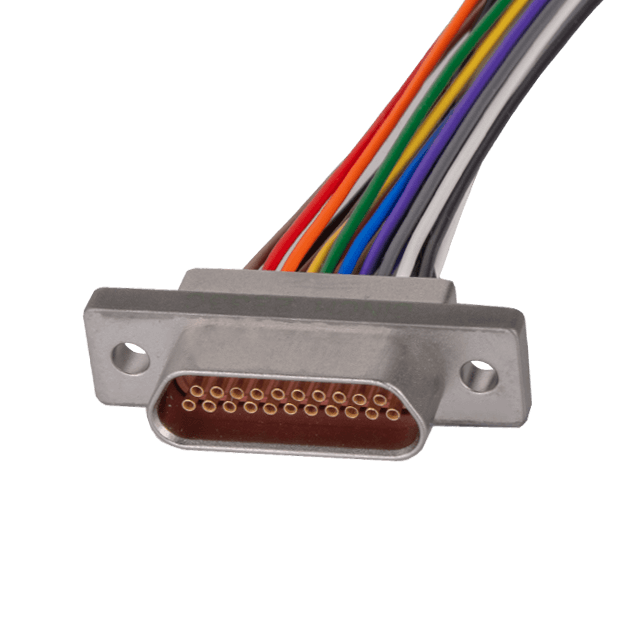

Trompeter Space Ready Products

Trompeter Space Ready Products

High-Density Stacking & Compression Solutions

High-Density Stacking & Compression Solutions

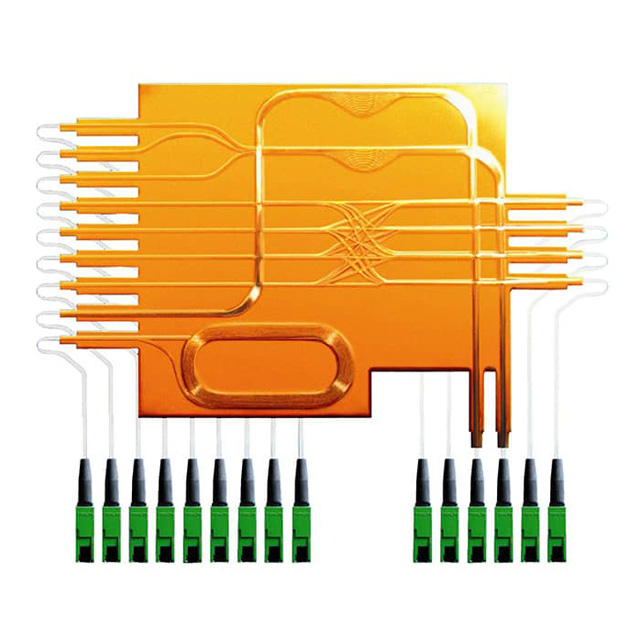

Fiber Flex Optical Circuits

Fiber Flex Optical Circuits