The development of military and aerospace systems presents a unique challenge. Modern platforms, whether aircraft, military vehicles, or naval vessels, contain intricate networks of subsystems that work in concert. As new technology becomes more capable, ensuring interoperability becomes even more critical.

This is made more complicated by increasingly long development cycles, with aircraft often taking a decade or more to reach frontline service. The cost and depth of this development cycle means that, once deployed, modern aircraft are expected to remain in use for decades. This long service life necessitates a consistent approach to upgrades in order to keep the platform up to date.

Optimizing Aerospace and Defense Systems with MIL-STD-1553

To address this need, the U.S. Department of Defense introduced MIL-STD-1553, a standardized digital communication protocol designed specifically for military and aerospace platforms. First implemented in 1973, MIL-STD-1553 provides a deterministic, fault-tolerant data bus architecture that ensures reliable, prioritized communication between onboard systems. Its adoption marked a turning point in how complex platforms manage internal data exchange.

Before MIL-STD-1553, system designers relied on proprietary solutions to link components together. This patchwork approach led to problems with the volume of wiring that was required, along with increased costs and significant delays in development. The introduction of a unified communication standard offered manufacturers and users a more efficient, interoperable, and future-proof solution.

Plug and Play Networking and Signal Prioritization

In the commercial world, users have become accustomed to the idea of “plug-and-play” functionality. This allows new equipment to be added to an existing network with little or no configuration required. Upgrading or extending such a network simply requires the creation of a physical connection, and a standardized network protocol to create a common communications link.

Networking protocols in the defense industry enable the same modular functionality, allowing platforms to be quickly updated, keeping them relevant and competitive. However, unlike networks in the commercial world, the communications within a complex platform such as an airplane or armored vehicle play critical roles in safety and reliability. The in-platform networking standard must therefore address several key requirements.

Flight Control Networks in Modern Military Aircraft

The first challenge to address is the sophistication of the systems in the network and the function they must perform. In one critical example, the data network of fourth-generation aircraft such as the F-16 is vital for flight safety. Unlike in previous aircraft, the pilot’s controls in the F-16 are not physically connected to the control surfaces. Instead, the flight control system receives inputs from the pilot and converts them into electrical signals. These in turn activate the control surfaces.

Figure 1: Digital Flight Control System

This use of computers to direct flight enabled the concept of relaxed stability, in which the aircraft is deliberately unstable. This creates an aircraft that is highly responsive and able to maneuver quickly. However, this makes it impossible for a pilot to control manually. The flight control computer instead relies on sensors to detect changes in motion, attitude, and acceleration. The computer then provides continuous automatic corrections to keep the aircraft stable and controllable. These signals must always receive the highest priority.

Deterministic Data Flow for Real Time Communication

Not all traffic traveling through the network is of equal importance, and it is essential that the network controller governs how information is shared. In many industrial bus-type systems, no such control exists. Each device on the network is free to share information at its own pace. If this were allowed to occur in an aerospace environment, critical data could be delayed. This is unacceptable if flight safety is put at risk.

Network Diagram of Bus Couplings

Any airborne network therefore needs to be deterministic. This means that the timing of communication is predictable and guaranteed and not left to chance. In a deterministic system, only the bus controller (BC) initiates communication. Remote terminals (RT), which include all subsystems connected to the network, can only transmit when authorized, eliminating any risk of collisions. Engineers know precisely when each message will be delivered, ensuring predictable timing across the network.

Key Advantages of Modular Upgrades

The key benefit for military platforms is that real-time systems such as flight controls can be given priority. It also means that integration of new components within the network is simple. As the timing of every message is prioritized by the BC, different subsystems can be developed separately with the confidence that they can be integrated smoothly when plugged into the bus.

This is the interoperability that is at the heart of the MIL-STD-1553 standard. Born in the early 1970s to address the growing complexity of aerospace systems, it delivers a unified approach to data exchange. The standard was first applied in the F-16 but quickly became a model for how to integrate sophisticated electronic systems.

MIL-STD-1553 also makes upgrading simple. As long as new components are designed to use the same common language, they can be added easily.

MIL-STD-1553 Components for Harsh Environments

However, the interoperability of MIL-STD-1553 does not rely solely on its digital protocol. Reliable data transfer depends on more than a set of rules for how information is exchanged. Instead, it requires a standardized way to connect the many subsystems that make up a modern aerospace or defense platform. Without secure and rugged connections, even the most sophisticated communication standard cannot deliver the interoperability and reliability that operators expect.

Military and aerospace environments are among the harshest encountered by human-made equipment. Aircraft are subjected to constant vibration, extremes of temperature, and exposure to lightning strikes and electromagnetic interference. Naval vessels must cope with salt spray and high humidity, both of which accelerate corrosion. Armored vehicles endure shock and vibration from traveling over uneven terrain, along with dust, grit, and weather. In each of these environments, the networks linking mission-critical systems cannot afford to fail. A weak connector or degraded cable can compromise the integrity of the bus, disrupting communication between critical systems. The consequences of such a failure could be severe, which is why the physical standards of MIL-STD-1553 connectivity are as vital as the protocol itself.

Designing Connectors to Withstand Harsh Operational Environments

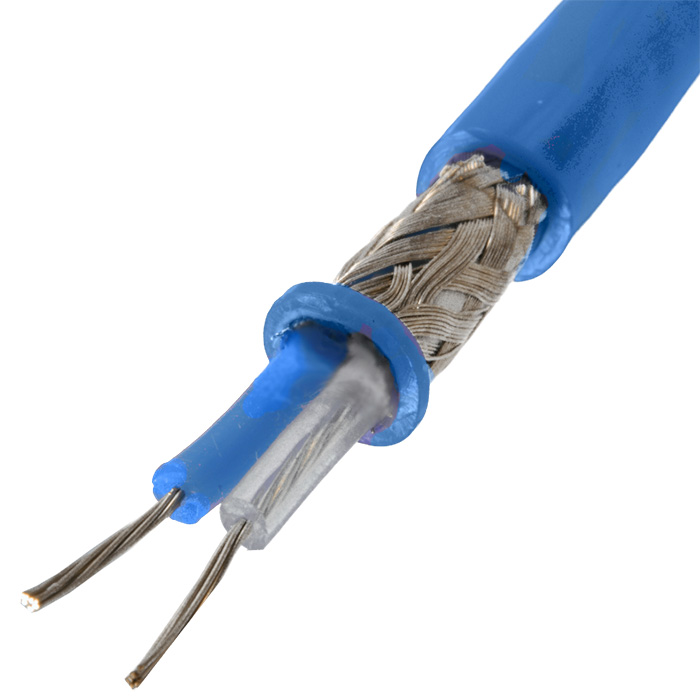

The physical layer of the standard is built around twin-axial cabling with a high-coverage shield, chosen for its resistance to electrical noise and electromagnetic interference. The connectors must preserve signal integrity while withstanding decades of mechanical and environmental stress.

As platforms remain in service for decades, connectors must deliver consistent performance over many years. They must maintain the shielding and impedance of the cable to prevent signal loss. Connectors must also resist moisture, dust, vibration, and corrosion, and they must lock securely to prevent disconnection during dynamic maneuvering.

MIL-STD-1553 Bus Architecture and Long-Term Connector Performance

MIL-STD-1553 requires dual-redundant data buses, and so connectors must also support architectures that provide reliable failover. This is the seamless switch from a primary channel to a redundant backup when the main system fails. This ensures that communication is maintained, even in the event of damage to one channel. Above all, they must adhere to standard designs, guaranteeing that subsystems from different manufacturers can be interconnected without compromising performance.

MIL-STD-1553 Bus Coupler Diagram

The interconnect industry has developed ruggedized connectors to meet these exacting demands. These are not simply commercial-grade parts adapted for military use, but purpose-built solutions designed with aerospace and defense environments in mind. They incorporate environmental sealing to prevent ingress of contaminants, shielding against electromagnetic interference, and robust locking systems that hold firm under vibration and shock. Many designs are optimized for maintainability, ensuring that they can be replaced or serviced quickly during scheduled maintenance without introducing new vulnerabilities. The result is a physical interface that reflects the same philosophy of reliability and longevity that lies at the heart of the MIL-STD-1553 protocol itself.

MIL-STD-1553 Components in Modern Aerospace and Defense Applications

Cinch Connectivity Solutions is one of the trusted providers of MIL-STD-1553 hardware, with decades of experience in developing rugged interconnect technology for aerospace and defense. Cinch has created a wide portfolio of connectors and accessories specifically designed for MIL-STD-1553 applications, offering the physical reliability that the digital protocol requires. Their products are engineered to withstand vibration, temperature extremes, and electromagnetic challenges. These connector solutions also deliver the precise electrical performance that keeps a MIL-STD-1553 rated data bus operating correctly. For system designers and operators, this means confidence that networks will continue to perform reliably across the long lifecycle of a platform, whether in original configuration or during mid-life modernization programs.

Cinch’s catalog includes solutions for aircraft, naval vessels, and armored vehicles, supporting both new integration and retrofit projects. Their product lines combine electrical integrity with environmental protection and long-term durability, ensuring that the physical layer of MIL-STD-1553 is as robust as the digital layer it supports. More detail on the full range of Cinch’s MIL-STD-1553 connectivity solutions can be found in our product listings.

Twinax and Triax Cable Assemblies

Twinax and Triax Cable Assemblies

RF and Microwave Cable Assemblies

RF and Microwave Cable Assemblies

MIL-STD-1553 Compliant Solutions

MIL-STD-1553 Compliant Solutions